Realizing innovations

Our customers profit from our proven expertise in delivering industry-leading compressors, components and systems for mobile and stationary applications. The scope of our services supports your organization in taking advantage of the opportunities provided by novel compressor technologies and by improved thermodynamics.

technology

selection

Technology chosen

for you

Any application requires the right choice of technology to be used prior to development. Regardless if at system or component level, we at OBRIST can look back on 20 years’ experience in that field and can carry out concept and matrix evaluations to find the right technology for any customer’s application.

We know what our customers need. From a blank slate to a functioning

A-Sample in the least amount of time, along with in-house capabilities in terms of research, simulations, hardware adjustments and testing.

- Benchmark analysis and patent research

- Concept / Evaluation matrix

- 3D & 2D Design Support

- Parts procurement

- Performance and NVH measurements

- Component teardown

simulation

Model-based simulation work helps to focus testing on the critical control and durability issues that require real-world testing.

Knowing before doing

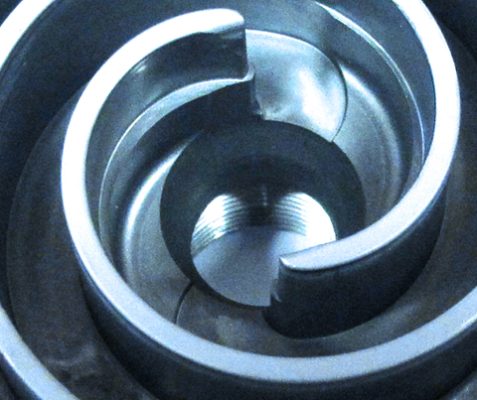

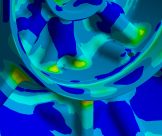

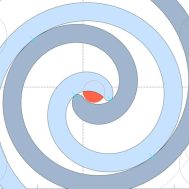

Once the right technology is chosen, profound simulation on system and component level is required to verify assumptions. We use state of the art CFD and FEA analysis tools combined with basic engineering experiences to find early and solution-orientated system and component design and size. Full in-house 3D and 2D design with all actual 3D systems is carried out at by a team with many years of experience. Short time loops with simulation results allow very fast 3D and 2D realisations.

Using a well-established basic dimensioning process minimizes failure rates and meets customers’ requirements. Our team of leading experts in thermal and fluid modelling supports the development process to get an early, deep understanding of the fluid and thermodynamics.

- Geometry Layout and Mechanical Design

- Compliance System (radial, axial, back-pressure)

- Leakage Optimisation, Tribology

- Dynamics, Bearing Life, Parts Durability

- Oil Management and Heat Transfer Optimisation

- Part Design (towards series production requirements)

Prototypes / Testing

A key milestone for a successful project. With a big network of specialized suppliers together with an in-house workshop and self-developed test stands, OBRIST’s development speed is unmatched.

Key people, key know-how

A well organised local network of prototype parts suppliers combined with in-house prototype building and testing allow very fast development times. If needed, we adapt or build test rigs for customer applications within the development project.

Full service development with fast and promising results that will astound.

- Test-rig Build-ups

- Reliable Supplier Network

- Precision Mechanics Specialists

- In-house Adjustments (at all times)

- Proper Workshops and Machines

Development

We support your engineering teams with our development services and our experience in multi-project management and are accustomed to working in international teams with our customers.

From idea to mass production

We can offer the full services needed for development from A-D sample. Depending on customer needs and requests, a handover of project can happen at any stage in the development. We typically support the handover and customer installation processes with consultancy.

Designing with state of the art product development processes. Field of competence reaches from concept studies to start of production level.

- Minimised Failure Rate

- Optimisation (from existing samples)

- Testing and Validation Process

- DFMEA / PFMEA / Control Plan

- Quality Audits, Concept and Detail Definition

- Continuous Improvement

Vehicle Build-Up

Over the past 20 years, OBRIST built-up several vehicles with new HVAC-systems for extensive testing. Special highlights of those are the R744 systems made for a variety of renowned OEM ‘s.

Show-car or demonstrator

you choose

AC and HP systems especially require testing and development within the target application. We can offer and carry out installation of these system in vehicles including measurement equipment, wind tunnel testing and evaluation of results.

Profound competencies through the build-up of more than 50 test vehicles equipped with R744 systems.

- A/C and Heat Pump Systems (single and dual)

- Additional Heating Systems

- Data Acquisition and Control

- Interior Air Quality Control