Realizing innovations

Our customers profit from our proven expertise in delivering industry-leading powertrain solutions. The scope of our services supports your organisation in taking advantage of the opportunities provided by novel propulsion technology and by optimised vehicle thermal management systems.

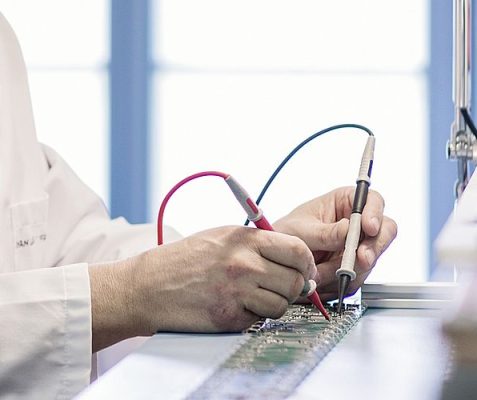

battery design

A key core of our know-how lies in the design and development of application-oriented HV and LV Li-ion battery systems.

Be Flexible

We have developed our own highly efficient and cost-optimised solution for use in a serial hybrid vehicle. In general, we rely on cylindrical 18650 cells. The main advantages of this cell technology are the continuously falling costs, the interchangeability, and manufacturer independence. In addition to battery variants with 18650 cells, concepts with pouch and prismatic cells were also developed through internal and customer projects.

As a thermal management expert, we also develop cooling concepts at the cell, module and battery level and integrate these into the overall vehicle thermal management concept.

Design Highlights

- Flexible Capacity

- Flexible Voltage Level

- Flexible Procurement

- Flexible Cell Chemistry

- Oil Management and Heat Transfer Optimisation

- Part Design (towards series production requirements)

Key Facts

- Development of HV und LV Li-ion Battery Systems

- Simple and Cost-optimized Solutions (for serial production)

- Development of Cooling Concepts (cell, module and battery)

- Integration into Vehicle Thermal Management

vehicle build-ups

A key strength of ours is the development of demonstration vehicles such as the HyperHybrid concept vehicle Mark I based on a Geely Emgrand EC7 and the Mark II based on a Tesla Model 3.

Showcar or demonstrator -

you name it

Drivetrain components were removed from the original vehicles and replaced by the HyperHybrid system components.

Corresponding mounting structures were designed with CAD and tested and secured by FEM. The optimum coordination between drivability / performance values and system consumption was then determined by means of test drives.

Construction of Concept Vehicles

- Basic Vehicles of All Kinds

- Test / Measurement of Selected Drivetrain Components and Auxiliary Units

- Mechanical Integration of Drivetrain Components and Auxiliary Units

- Adapt Existing and Interpret New Structures

- Packaging Examinations via CAD

- Strength Analysis with FEM

- Electrical Integration of Drivetrain Components and Auxiliary Units

- Interface Analysis Vehicle Drivetrain Components / Auxiliary Units

- Hardware and Software Integration

- Integration of Online Parameter Recording and Analysis Functions

- Hybrid Control and Operational Strategy Development

- Vehicle Tests

- Planning / Support for Surveying on Roller Test Stand

Key Facts

- Concept and Feasibility Studies

- Prototyping of Components

- Component Measurement and Optimization

- System Measurement and Optimization

- Vehicle Erection and Conversion

simulation / testing

In principle, any vehicle with HyperHybrid components can be equipped and simulated to make the advantages / strengths of the developed concept visible.

Technology chosen for you

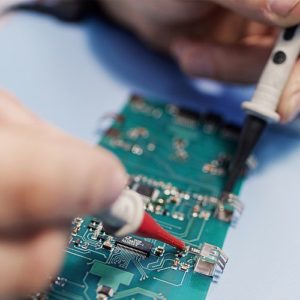

During the development of the “HyperHybrid” system, a component test stand was constructed. It was used for the initial commissioning of the main system components (ZV Generator HICE, HV battery, and drive system) to ensure the performance and efficiency values for the simulation.

The test stands are indispensable for measuring and optimizing existing and developing new or improved components.

Simulation Target

Presentation of certain hyperhybrid system advantages

- Customer Request via Simulation Requirement Sheet

- Detection of Real Vehicle Characteristics

- Detection of the Components (to be replaced / added)

- Installation and Mass Focal Point Investigation

- Design HyperHybrid Vehicle

- Supply of the Components

- Adjustment of the Components (according to the simulation goal)

- Subsequent Simulation Loops

- Documentation of the Results

- Presentation Creation

- Presentation and Discussion (with customers)

Key facts

1. Simulation

- BEV and Serial Hybrid Vehicles (of all classes: economy, luxury class, sports vehicles)

- Misc. Vehicle Types (small cars, luxury sedans, SUVs, buses, trucks)

- Misc. Drive Modes (FWD, RWD, AWD

- Acceleration Tests (constant driving, downhill runs, standard driving cycles and also real driving with speed and height profile)

2. Testing

- Component Tests (Battery, E-Drive and REX)

- Operation of the Components (in the system network)

- Actual State Analysis

- Determination of Potential for Improvement

- Implementation / Re-testing of Improvements

Extensive Test Possibilities

- HV Battery Tests

- REX Tests

- E-Drive Tests

powertrain thermal management

Our Powertrain and Engineering teams have many years of experience in design and efficiency optimisation of the thermal management of complete vehicle systems.

Thermal comfort

More than 50 vehicles have been equipped for the most diverse OEMs and suppliers. We have a comprehensive network of partners which ensures the development and delivery of the required components. The wide range of know-how and acquired years of experience in automotive thermal management enables us to develop and implement holistic concepts for air conditioning of the interior, drive train components (electric motor, inverter) and HV battery as well as Range Extender high temperature circuits.

Thermo-management: Vehicle and Powertrain

- Cooling (cell, cell module, battery)

- Drive Motor Inverter Cooling (low temperature cooling circuits)

- REX Cooling (high temperature cooling circuit)

- Interior Cooling

- Oil Management and Heat Transfer Optimisation

- Part Design (towards series production requirements)

Key Facts

- Years of Experience

- Comprehensive Network of Partners

- Holistic Climate Control Concepts